Are you interested in Argotherm furnace for Sintron system?

Contact us to learn how the Sintron system works

No products in the cart.

$369.00 – $699.00

Milling metal like wax. A sophisticated system for the fabrication of non-precious metal restorations. Developed in cooperation with the Fraunhofer IFAM Institut Dresden.

Milling metal like wax. A sophisticated system for the fabrication of non-precious metal restorations. Developed in cooperation with the Fraunhofer IFAM Institut Dresden.

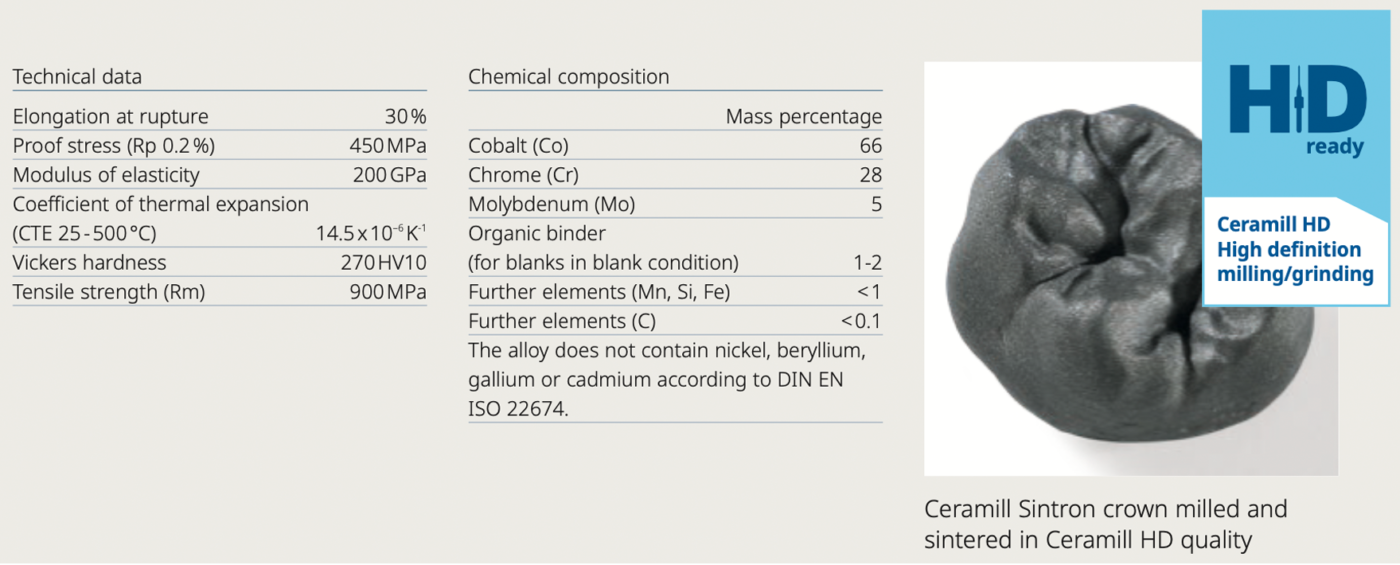

High innovation strength is incorporated in the Ceramill Sintron CoCr sinter metal. The non-precious metal revolutio- nises the manufacturing pro- cess, as the wax-like texture of the Ceramill Sintron blanks allows them to be effortlessly dry milled on inhouse bench- top machines such as the Ceramill Motion. The labour- intensive and error-prone casting procedure and there- fore time-consuming manual working stages are no longer required. The sinter process is also extremely easy: the press of a button is sufficient for producing a framework with excellent structure quality. Maximum process reliability produces homogeneous, distortion-free frameworks without contraction cavities. Using the new Ceramill Sintron it is possible to achieve pre- dictable, reproducible fit and framework quality. Ceramill Sintron can be veneered using any CoCr framework porcelain.

Are you interested in Argotherm furnace for Sintron system?

| Thickness | 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 25mm |

|---|