AG Zolid HT+ preshade zirconia

$169.00 – $199.00

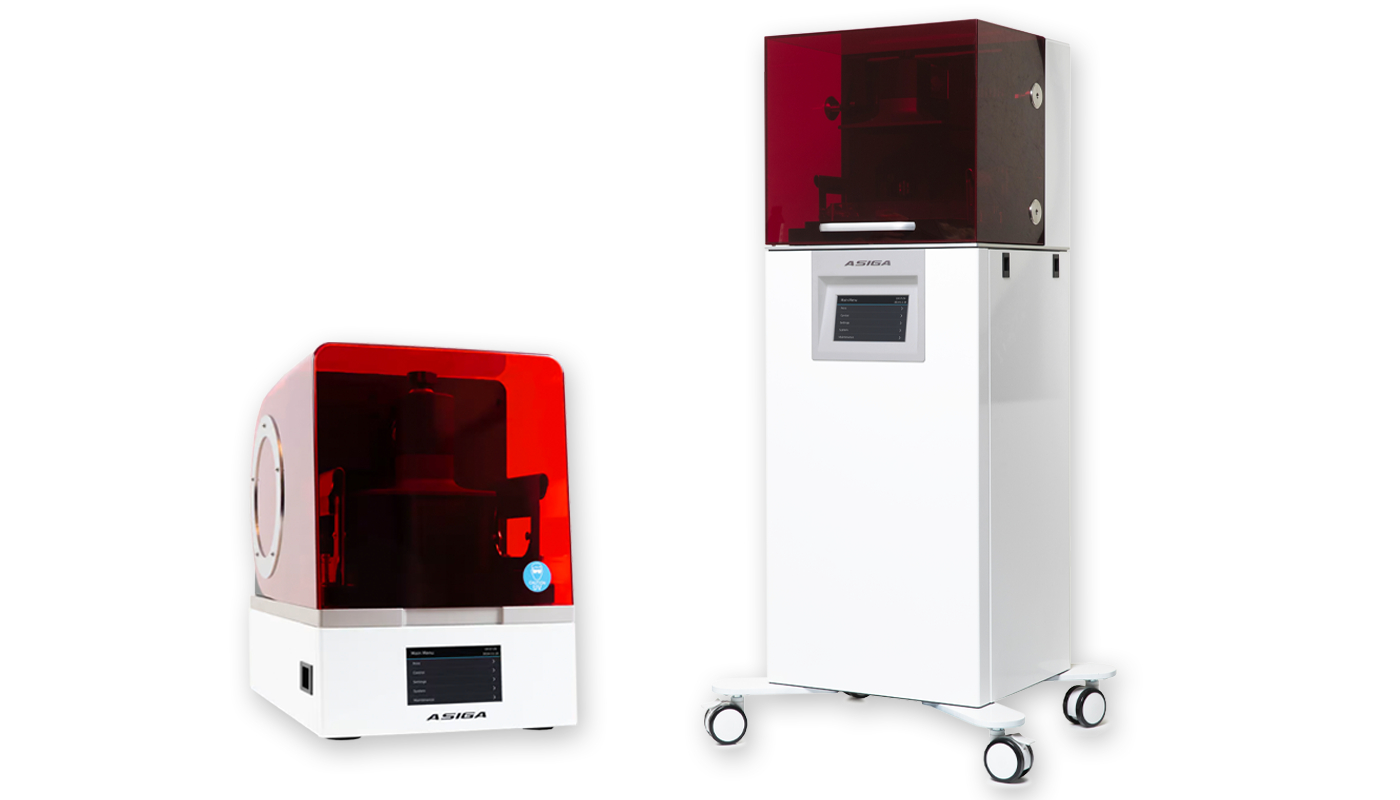

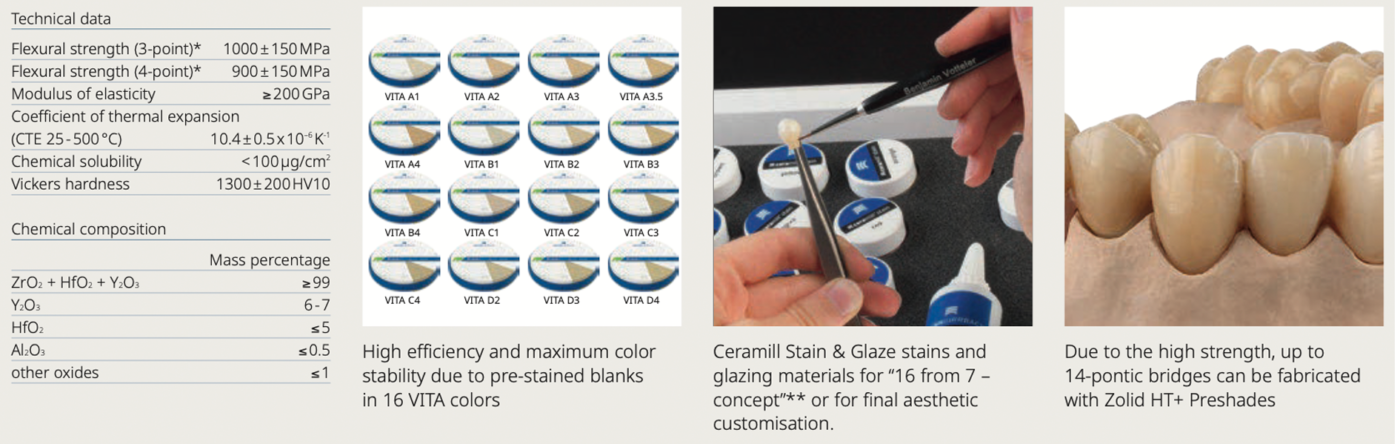

High efficiency and excellent esthetics: both are combined in the highly translucent Zolid HT+ Preshades zirconia, thus making it suitable for a wide range of indications.

- Flexural strength 1000 Mpa

- High translucency+

14mm

16mm

20mm

Bleach

$169.00

$179.00

$199.00

A1

$169.00

$179.00

$199.00

A2

$169.00

$179.00

$199.00

A3

$169.00

$179.00

$199.00

A3.5

$169.00

$179.00

$199.00

A4

$169.00

$179.00

$199.00

B1

$169.00

$179.00

$199.00

B2

$169.00

$179.00

$199.00

B3

$169.00

$179.00

$199.00

B4

$169.00

$179.00

$199.00

C1

$169.00

$179.00

$199.00

C2

$169.00

$179.00

$199.00

C3

$169.00

$179.00

$199.00

C4

$169.00

$179.00

$199.00

D2

$169.00

$179.00

$199.00

D3

$169.00

$179.00

$199.00

D4

$169.00

$179.00

$199.00