Zolid Gen-X – Esthetic all-rounder

Zolid Gen-X puts an end to the time-consuming search for the right blank for the popular res- toration, quite simply because the latest blanks of the Zolid DNA generation are true all-rounders!

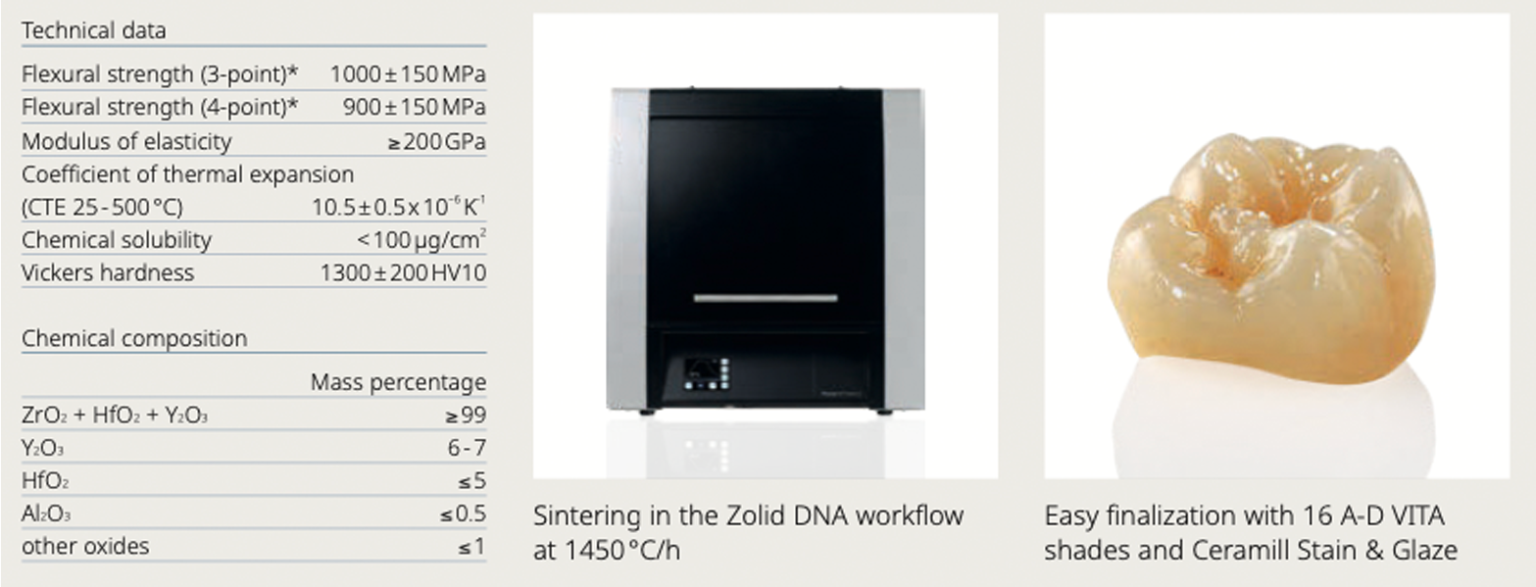

Zolid Gen-X combines all the advantages of the Zolid HT+ product group: the excellent esthetic properties and out- standing mechanical values allow exceeding any indication limitations.

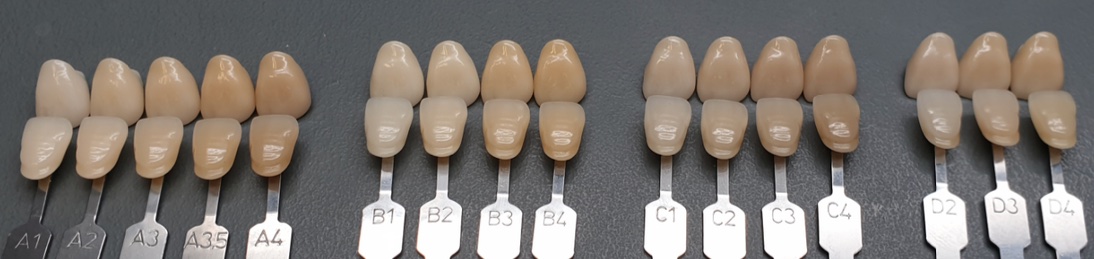

In addition, Gen-X possesses a natural color gradient that takes the blank to a new level in terms of efficiency and esthetics.